Abstract

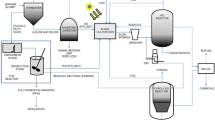

Dairy operations constitute ~2.5% of annual U.S. greenhouse gas (GHG) emissions, making dairies one of the largest sources of industrial GHG emissions. We are developing a novel, integrated system to achieve a net reduction in dairy GHGs while producing value-added materials and products. This integrated manure-to-commodities system converts dairy manure to bioenergy, sequesters carbon by converting volatile fatty acid-rich fermenter supernatant to bioplastics, and utilizes anaerobic digester (AD) and polyhydroxyalkanoate (PHA) reactor effluents to produce algae that can be harvested and internally recycled to enhance PHA production and sequester carbon. A decision-making tool is being developed for the integrated system that quantifies net GHG reduction, carbon sequestration, nutrient management and economics.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Preview

Unable to display preview. Download preview PDF.

Similar content being viewed by others

References

USDA ERS (2015), U.S. milk production and related data, http://www.ers.usda.gov/data-products/dairy-data.aspx, June 25, 2015.

BSSC (2008). U.S. Dairy Sustainability Initiative: A roadmap to reduce greenhouse gas emissions and increase business value. Internet. Innovation Center for U.S. Dairy.

Liebrand C.B. & Ling K.C. (2009). Cooperative approaches for implementation of dairy manure digesters. In: (ed. USDA). USDA-Rural Development, p. 28.

USEPA (2014). Emissions & Generation Resource Integrated Database (eGRID) 9th edition Version 1.0 Year 2010 Summary Tables, updated 02/24/2014, http://www.epa.gov/cleanenergy/energy-resources/egrid/

USEPA (2011). Market Opportunities for Biogas Recovery Systems at U.S. Livestock Facilities. AgSTAR. Internet.

Zaks, D.P.M., Winchester, N., Kucharik, C.J., Barford, C.C., Paltsev, S. and Reilly, J.M. (2011). Contribution of anaerobic digesters to emissions mitigation and electricity generation under U.S. climate policy. Environ. Sci. Technol., 45, 6735–6742.

Coats E. et al. (2013). An integrated two-stage anaerobic digestion and biofuel production process to reduce life cycle GHG emission from US dairies. Biofuels Bioproducts & Biorefining 7, 459–473.

Stowe, E.J., Coats, E.R., and Brinkman, C.K. (2015). Dairy manure resource recovery utilizing two-stage anaerobic digestion—Implications of solids fractionation, Bioresource Technology 198, 237–245.

Steinbüchel, A. and Lütke-Eversloh, T. (2003) Metabolic engineering and pathway construction for biotechnological production of relevant poly hydroxy alkanoates in microorganisms, Biochem Eng J 16, 81–96.

Anon (1989). Modern Plastics Encyclopedia. 11 edn. McGraw Hill Inc., NY.

Madison L.L. & Huisman G.W. (1999). Metabolic engineering of poly (3-hydroxyalkanoates): from DNA to plastic. Microbiol Mol. Biol Rev., 63, 21–53.

Zinn M., Witholt B. & Elgi T. (2001). Occurrence, synthesis and medical application of bacterial polyhydroxyalkanoate. Advan. Drug Deliv. Rev., 53, 5–21.

Wei, L, Liang, S., Coats, E.R., and McDonald, A.G. (2015). Valorization of residual bacterial biomass waste after polyhydroxyalkanoate isolation by hydrothermal treatment, Bioresource Technology, in 2 review.

Wei, L., Guho, N., Coats, E.R., McDonald, A.G, (2014) Characterization of poly(3-hydroxybutyrate-co-3-hydroxyvalerate) biosynthesized by mixed microbial consortia fed fermented dairy manure, Journal of Applied Polymer Science 131(11), 5516–5528.

Quinn, J., de Winter, L., and Bradley, T. (2011). Microalgae bulk growth model with application to industrial scale system. Bioresource Technology, 102, 5083–5092.

Juenja A., Ceballos R.M., and Murthy, GS. (2013). Effects of environmental factors and nutrient availability on the biochemical composition of algae for biofuels production: a review. Energies, 6, 4607–4638.

Jones, S.B., Zhu, Y., Anderson, D.B., Hallen, R.T., Elliott, D.C., Schmidt, A.J., Albrecht, K O., Hart, TR., Butcher, M.G, Drennan, D., Snowden-Swan, L.J., Davis, R., Kinchin, C. (2014) Process design and economics for the conversion of algal biomass to hydrocarbons: whole algae hydrothermal liquefaction and upgrading. PNNL-23227, Pacific Northwest National Laboratory, Richland, Washington, USA.

Chakraborty et al. (2013). Ana-glucan isolated as a co-product of biofuel by hydrothermal liquefaction of Chlorella sorokiniana biomass, Algal Research 2, 230–236.

Liang, S., Wei, L, Passero, M., Ferris, K., McDonald, A.G, (2015) Hydrothermal treatment of algae, in preparation.

Liang, S., Han, Y., Wei, L, McDonald, A.G, (2015) Production and characterization of bio-oil and bio-char from pyrolysis of potato peel wastes. Biomass Conversion and Biorefinery. 5(3): 237–246.

Wei, L, Liang, S., Guho, N.M., Hanson, A. J., and McDonald, A.G. (2015). Production and characterization of bio-oil and biochar from the pyrolysis of residual bacterial biomass from a polyhydroxyalkanoate production process, Journal of Analytical and Applied Pyrolysis, DOI: 10.1016/j.jaap2015.08.005..

Chen, S. et al. (2003). Value-Added Chemicals from Animal Manure: Final Technical Report Northwest Bioproducts Research Institute, Pacific Northwest National Laboratory Report PNNL-14495.

Artrip K.G., Shrestha, D.S., Coats E., and Keiser D.(2013). GHG emissions reduction from an anaerobic digester in a dairy farm: theory and practice. Applied Engineering in Agriculture 29 (5): 729–737.

USDA ERS (2015), U.S. milk production and related data (quarterly), http://www.ers.usda.gov/data-products/dairy-data.aspx, June 27, 2015.

ASABE (2005). Manure Production and Characteristics. ASAE Standard D384.2. March 2005. American Society of Biological and Agricultural Engineers. St Joseph, Michigan.

Ley tem, A.B., Dungan, RS. Bjorneberg, D.L., and Koehn A.C. (2011). Emissions of Ammonia, Methane, Carbon Dioxide, and Nitrous Oxide from Dairy Cattle Housing and Manure Management Systems, Journal of Environmental Quality, Vol. 40, 1383–1394.

IPCC (2007). Fourth Assessment Report Chapter 2: Changes in Atmospheric Constituents and in Radiative Forcing. Table 2.14, page 212.

Davis R et al (2012). Renewable Diesel from Algal Lipids: An Integrated Baseline for Cost, Emissions, and Resource Potential from a Harmonized Model. U.S. DOE Biomass Program.

Dalrymple O.K. et al. (2013). Wastewater use in algae production for generation of renewable resources: a review and preliminary results. Aquatic Biosystems 9(2).

Slade, R and Bauen A. (2013). Micro-algae cultivation for biofuels: Cost, energy balance, environmental impacts and future prospects. Biomass and Bioenergy, 29–38.

Informa Economics (2013). National Market Value of Anaerobic Digester Products. Informa Economics, Inc.

Topper, P. A., Graves, RE., Richard, T.. (2006). The Fate of Nutrients and Pathogens During Anaerobic Digestion of Dairy Manure (G-71). Penn State Extension.

Perry, R.H and Chilton, C.H (1973). Chemical Engineers’ Handbook, McGraw-Hill Book Co., New York, 25–16.

USDA FSA (2014). Farm Loan Programs: Farm Operating Loans & Microloans. USDA Farm Service Agency. Internet. https://www.fsa.usda.gov/FSA/webapp?area=home&subject=fmlp&topic=dflop

USEPA (1999). U.S. Methane Emissions 1990–2010: Inventories, Projections, and Opportunities for Reductions. Internet.

Borton, LR, Rotz, CA., Person, H.L, Harrigan, T.M., and Bickert, W. G (1995). Simulation to Evaluate Dairy Manure Systems, Applied Engineering in Agriculture 11(2), 301–310.

EIA. (2014). Electricity Data Browser. Internet. http://www.eia.gov/electricity/data/browser.

Fang, Z. (2013). Pretreatment techniques for biofuels and biorefineries. Berlin: Springer.

Jirka, S., & Tomlinson, T. (2014). 2013 State of the Biochar Industry—A Survey of Commercial Activity in the Bioc har Field. 20–20.

Eicher, A. (2013). Comparison of Biomass to Bio-oils Reactor Systems: Direct Conversion vs. Companion Coal Gasification. 1–1. Retrieved from http://scholars.unh.edu/cgi/viewcontent.cgi?article=1105&context=honors

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2016 TMS (The Minerals, Metals & Materials Society)

About this chapter

Cite this chapter

Wendt, C., Ellis, C., Guillen, D.P., Feris, K., Coats, E.R., McDonald, A. (2016). Reduction of GHG Emissions through the Conversion of Dairy Waste to Value-Added Materials and Products. In: Li, L., et al. Energy Technology 2016. Springer, Cham. https://doi.org/10.1007/978-3-319-48182-1_13

Download citation

DOI: https://doi.org/10.1007/978-3-319-48182-1_13

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-48619-2

Online ISBN: 978-3-319-48182-1

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)