Abstract

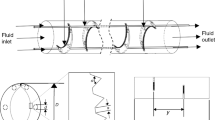

In the present work, heat transfer and pressure drop characteristics in flow through a tube with inline and staggered baffles having angular cut at the edge are reported for various operating conditions. An experimental test rig is designed and developed to investigate heat transfer and pressure drop behavior for different conditions. Effects of different geometrical parameters, i.e., pitch ratios, baffle arrangement and cutting angle of baffles on heat transfer rate and pressure drop characteristics, have been investigated for turbulent flow regime. Reynolds number ranging from 10,000 to 52,000 has been considered in the present study. The maximum heat transfer rate has been observed for staggered arrangement with pitch ratio of 0.1 and cutting angle of 60°, while minimum heat transfer rate has been observed for inline arrangement with pitch ratio of 0.2 and cutting angle of 30°. Empirical correlations for Nusselt number and friction factor have been developed as a function of geometrical and flow parameters. The deviations between experimental and predicted values of Nusselt number and friction factor for staggered arrangements have been observed as ± 10%, ± 4%, respectively, whereas for inline arrangement the deviation has been observed as ± 12%, ± 5%, respectively. Results from empirical correlations are well agreed with the experimental data.

Similar content being viewed by others

Abbreviations

- A :

-

Tube inner wall surface area (m2)

- b :

-

Breadth of baffle (m)

- c p :

-

Mean isobaric heat capacity (J kg−1 K−1)

- d :

-

Perforation depth (m)

- D :

-

Inner diameter of test tube (m)

- D’ :

-

Diameter defining baffle shape (m)

- E :

-

Eccentricity in defining baffle shape (m)

- f:

-

Darcy friction factor

- h :

-

Convective heat transfer coefficient (W m−2 K−1)

- H :

-

Perforation ratio

- I :

-

Current (A)

- k :

-

Fluid thermal conductivity (W mK−1)

- L :

-

Tube length (m)

- m :

-

Mass flow rate (kg s−1)

- Nu:

-

Nusselt number

- Δp :

-

Pressure drop (N m−2)

- P :

-

Pitch ratio

- Pr :

-

Prandtl number

- R w :

-

Wall thermal resistance (K W−1)

- q w :

-

Wall heat flux

- Re:

-

Reynolds number based on D and V

- T :

-

Temperature (K)

- t :

-

Baffle thickness (m)

- V :

-

Bulk velocity for plain tube (m s−1); voltage (V)

- W :

-

Height of baffle (m)

- y :

-

Pitch (m)

- ρ :

-

Fluid density (kg m−3)

- α :

-

Cut angle (°)

- b:

-

Bulk

- e:

-

Electric

- i:

-

Inlet

- o:

-

Outlet

- ow:

-

Outer wall

- w:

-

Inner wall

- 0:

-

Plain tube (turbulator free)

- SACB:

-

Staggered angular cut baffle

- IACB:

-

Inline angular cut baffle

References

Kabeel AE, El-Said EMS. A hybrid solar desalination system of air humidification, dehumidification and water flashing evaporation: Part II. Experimental investigation. Desalination. 2014;341:50–60.

El-Said EMS, Kabeel AE, Abdulaziz M. Theoretical study on hybrid desalination system coupled with nano-fluid solar heater for arid states. Desalination. 2016;386:84–98.

Kabeel AE, El-Said EMS. Experimental study on a modified solar power driven hybrid desalination system. Desalination. 2018;443:1–10.

El-Said EMS, Abdulaziz M, Awad MM. A numerical investigation on heat transfer enhancement and the flow characteristics in a new type plate heat exchanger using helical flow duct. Cogent Eng. 2017;4:1396638.

El-Said EMS, Abdulaziz M, Awad MM. Thermodynamic performance evaluation for helical plate heat exchanger based on second law analysis. Proc Roman Acad Ser A. 2018;19:237–42.

El-Said EMS, Abou Alsood MM. Experimental investigation of air injection effect on the performance of horizontal shell and multi-tube heat exchanger with baffles. Appl Therm Eng. 2018;134:238–47.

El-Said EMS, Abou Al-Sood MM. Shell and tube heat exchanger with new segmental baffles configurations: a comparative experimental investigation. Appl Therm Eng. 2019;150:803–10.

Saeedan M, Solaimany Nazar AR, Abbasi Y, Karimi R. CFD Investigation and neutral network modeling of heat transfer and pressure drop of nanofluids in double pipe helically baffled heat exchanger with a 3-D fined tube. Appl Therm Eng. 2016;100:721–9.

Liu J, Qian C. Comparison of the fluid flow and heat transfer in shell-and-tube heat exchangers with different baffles and tubes: simulation and experimental studies. Asia-Pac J Chem Eng. 2016;11:1051–9.

Sahel D, Ameur H, Benzeguir R, Kamla Y. Enhancement of heat transfer in a rectangular channel with perforated baffles. Appl Therm Eng. 2016;101:156–64.

Qiu Y, Li M-J, Wang W-Q, Du B-C, Wang K. An experimental study on the heat transfer performance of a prototype molten-salt rod baffle heat exchanger for concentrated solar power. Energy. 2018;156:63–72.

Wang S, Jiang X, Wang R, Wang X, Yang S, Zhao J, Liu Y. Numerical simulation of flow behavior of particles in a liquid-solid stirred vessel with baffles. Adv Powder Technol. 2017;28:1611–24.

Anil K, Man-Hoe K. Thermal hydraulic performance in a solar air heater channel with multi V-type perforated baffles. Energies. 2016;9:564.

Gajusingh ST, Shaikh N, Siddiqui K. Influence of a rectangular baffle on the downstream flow structure. Exp Therm Fluid Sci. 2010;34:590–602.

Kumar R, Chauhan R, Sethi M, Kumar A. Experimental study and correlation development for Nusselt number and friction factor for discretized broken V-pattern baffle solar air channel. Exp Therm Fluid Sci. 2017;81:56–75.

Momin AME, Saini JS, Solanki SC. Heat transfer and friction in solar air heater duct with V-shaped rib roughness on absorber plate. Int J Heat Mass Transf. 2002;45:3383–96.

Han JC, Zhang YM, Lee CP. Augmented heat transfer in square channels with parallel, crossed and V-shaped angled ribs. ASME J Heat Transf. 1991;113:590–6.

Han JC, Zhang YM, Lee CP. Influence of surface heat flux ratio on heat transfer augmentation in square channels with parallel, crossed, and V-shaped angled ribs. ASME J Turbomach. 1992;114:872–80.

Kumar A, Kim M-H. Thermal hydraulic performance in a solar air heater channel with multi V-Type perforated baffles. Energies. 2016;9:564.

Alfarawi S, Abdel-Moneim SA, Bodalal A. Experimental investigations of heat transfer enhancement from rectangular duct roughened by hybrid ribs. Int J Therm Sci. 2017;118:123–38.

Kwankaomeng Sutapat, Promvonge Pongjet. Numerical prediction on laminar heat transfer in square duct with 30° angled baffle on one wall. Int Commun Heat Mass Transf. 2010;37:857–66.

Salem MR, Althafeeri MK, Elshazly KM, Higazy MG, Abdrabbo MF. Experimental investigation on the thermal performance of a double pipe heat exchanger with segmental perforated baffles. Int J Therm Sci. 2017;122:39–52.

Ary BKP, Lee MS, Ahn SW, Lee DH. The effect of the inclined perforated baffle on heat transfer and flow patterns in the channel. Int Commun Heat Mass Transf. 2012;39:1578–83.

Lee CK, Abdel-Moneim SA. Computational analysis of heat transfer in turbulent flow past a horizontal surface with two-dimensional ribs. Int Commun heat mass Transf. 2001;28(2):161–70.

Gradeck M, Hoareau B, Lebouche M. Local analysis of heat transfer inside corrugated channel. Int J Heat Mass Transf. 2005;48(10):1909–15.

Vazquez MS, Rodríguez WV, Issa R. Effects of ridged walls on the heat transfer in a heated square duct. Int J Heat Mass Transf. 2005;48(10):2050–63.

Sriromreun P, Thianpong C, Promvonge P. Experimental and numerical study on heat transfer enhancement in a channel with Z-shaped baffles. Int Commun Heat Mass Transf. 2012;39:945–52.

Ko K-H, Anand NK. Use of porous baffles to enhance heat transfer in a rectangular channel. Int J Heat Mass Transf. 2003;46:4191–9.

Nuntadusit C, Piya I, Wae-hayee M, Eiamsa-ard S. Heat transfer characteristics in a channel fitted with zigzag-cut baffles. J Mech Sci Technol. 2015;29:2547–54.

Gajusingh ST, Shaikh N, Siddiqui K. Influence of a rectangular baffle on the downstream flow structure. Exp Therm Fluid Sci. 2010;34:590–602.

Roetzel W, Lee DW. Effect of baffle/shell leakage flow on heat transfer in shell-and-tube heat exchangers. Exp Therm Fluid Sci. 1994;8:10–20.

Roetzel W, Lee D. Effect of baffle/shell leakage flow on heat transfer in shell-and-tube heat exchangers. Exp Therm Fluid Sci. 1993;7:131.

Alam T, Saini RP, Saini JS. Experimental investigation of thermohydraulic performance of a rectangular solar air heater duct equipped with V-shaped perforated blocks. Adv Mech Eng. 2014;6:948313.

Singh SK, Kumar M, Kumar A, Gautam A, Chamoli S. Thermal and friction characteristics of a circular tube fitted with perforated hollow circular cylinder inserts. Appl Therm Eng. 2018;130:230–41.

Bhattacharyya S, Chattopadhyay H, Benim AC. 3D CFD Simulation on heat transfer enhancement in turbulent channel flow with twisted tape inserts. Prog Comput Fluid Dyn Int J. 2017;17:193–7.

Saha S, Bhattacharyya S, Dayanidhi G. Enhancement of heat transfer of laminar flow of viscous oil through a circular tube having integral axial rib roughness and fitted with helical screw-tape inserts. Heat Transf Res. 2012;43:207–27.

Bhattacharyya S, Benim AC, Chattopadhyay H, Banerjee A. Experimental investigation of heat transfer performance of corrugated tube with spring tape inserts. Exp Heat Transf. 2018;32:1–15.

Bhattacharyya S, Chattopadhyay H, Guin A, Benim AC. Investigation of inclined turbulators for heat transfer enhancement in a solar air heater. Heat Transf Eng. 2018;40:1–10.

S. Bhattacharyya, A.C. Benim, H. Chattopadhyay, A. Banerjee, Experimental and numerical analysis of forced convection in a twisted tube (accepted). J Therm Sci (http://thermalscience.vinca.rs/). (2019).

Bhattacharyya S, Chattopadhyay H, Benim A. Numerical investigation on heat transfer in a circular tube with inclined ribs. Prog Comput Fluid Dyn Int J. 2017;17:390–6.

Bhattacharyya S, Chattopadhyay H, Banerjee A, Benim AC. Heat transfer and flow field in a circular twisted channel. MATEC Web Conf. 2018;240:01005.

Bhattacharyya S. Experimental study on effect of heat transfer enhancement of heat exchanger tube inserted with short length spring tapes. Iran J Sci Technol Trans Mech Eng. 2018. https://doi.org/10.1007/s40997-018-0251-0.

Saha S, Saha SK. Enhancement of heat transfer of laminar flow through a circular tube having integral helical rib roughness and fitted with wavy strip inserts. Exp Therm Fluid Sci. 2013;50:107–13.

Saha SK. Thermohydraulics of laminar flow of viscous oil through a circular tube having axial corrugations and fitted with centre-cleared twisted-tape. Exp Therm Fluid Sci. 2012;38:201–9.

Saha SK. Thermohydraulics of laminar flow through a circular tube having integral helical corrugations and fitted with helical screw-tape insert. Chem Eng Commun. 2013;200:418–36.

Saha SK, Bhattacharyya S, Pal PK. Thermohydraulics of laminar flow of viscous oil through a circular tube having integral axial rib roughness and fitted with center-cleared twisted-tape. Exp Therm Fluid Sci. 2012;41:121–9.

Meyer JP, Everts M. Single-phase mixed convection of developing and fully developed flow in smooth horizontal circular tubes in the laminar and transitional flow regimes. Int J Heat Mass Transf. 2018;117:1251–73.

Bhattacharyya S, Chattopadhyay H, Haldar A. Design of twisted tape turbulator at different entrance angle for heat transfer enhancement in a solar heater. Beni-Suef Univ J Basic Appl Sci. 2018;7:118–26.

Bhattacharyya S, Dey K, Hore R, Banerjee A, Paul AR. Computational study on thermal energy around diamond shaped cylinder at varying inlet turbulent intensity. Energy Proc. 2019;160:285–92.

Bhattacharyya S, Chattopadhyay H, Saha SK. Numerical study on heat transfer enhancement of laminar flow through a circular tube with artificial rib roughness. J Refrig Air Cond Heat Vent. 2014;1:14–9.

Bhattacharyya S, Saha S, Saha SK. Laminar flow heat transfer enhancement in a circular tube having integral transverse rib roughness and fitted with centre-cleared twisted-tape. Exp Therm Fluid Sci. 2013;44:727–35.

Shah RK, Sekulić DP. Fundamentals of heat exchanger design. New York: Wiley; 2003.

Wang W, Zhang Y, Li B, Li Y. Numerical investigation of tube-side fully developed turbulent flow and heat transfer in outward corrugated tubes. Int J Heat Mass Transf. 2018;116:115–26.

Chang SW, Yang TL, Liou JS. Heat transfer and pressure drop in tube with broken twisted tape insert. Exp Therm Fluid Sci. 2007;32:489–501.

Promvonge P. Thermal performance in circular tube fitted with coiled square wires. Energy Convers Manag. 2008;49:980–7.

Tang X, Dai X, Zhu D. Experimental and numerical investigation of convective heat transfer and fluid flow in twisted spiral tube. Int J Heat Mass Transf. 2015;90:523–41.

Mohammed HA, Abbas AK, Sheriff JM. Influence of geometrical parameters and forced convective heat transfer in transversely corrugated circular tubes. Int Commun Heat Mass Transf. 2013;44:116–26.

Eiamsa-ard S, Rattanawong S, Promvonge P. Turbulent convection in round tube equipped with propeller type swirl generators. Int Commun Heat Mass Transf. 2009;36:357–64.

Bhuiya MMK, Chowdhury MSU, Ahamed JU, Khan MJH, Sarkar MAR, Kalam MA, Masjuki HH, Shahabuddin M. Heat transfer performance for turbulent flow through a tube using double helical tape inserts. Int Commun Heat Mass Transf. 2012;39:818–25.

Suri ARS, Kumar A, Maithani R. Experimental determination of enhancement of heat transfer in a multiple square perforated twisted tape inserts heat exchanger tube. Exp Heat Transf. 2018;31:85–105.

Kumar A, Kumar R, Chauhan R, Sethi M, Kumari A, Verma N, Nadda R. Single-phase thermal and hydraulic performance analysis of a V-pattern dimpled obstacles air passage. Exp Heat Transf. 2017;30:393–426.

Chang SW, Chen TW, Chen YW. Detailed heat transfer and friction factor measurements for square channel enhanced by plate insert with inclined baffles and perforated slots. Appl Therm Eng. 2019;159:113856.

Eiamsa-ard S, Ruengpayungsak K, Thianpong C, Pimsarn M, Chuwattanakul V. Parametric study on thermal enhancement and flow characteristics in a heat exchanger tube installed with protruded baffle bundles. Int J Therm Sci. 2019;145:106016.

Sahel D, Ameur H, Benzeguir R, Kaml Y. Enhancement of heat transfer in a rectangular channel with perforated baffles. Appl Therm Eng. 2016;101:156–64.

Nanan K, Thianpong C, Pimsarn M, Chuwattanakul V, Eiamsa-ard S. Flow and thermal mechanisms in a heat exchanger tube inserted with twisted cross-baffle turbulators. Appl Therm Eng. 2017;114:130–47.

Acknowledgements

The authors would like to gratefully acknowledge Sam Casting (Grant No. 01/2014), University of Pretoria, MCKV Institute of Engineering and Jadavpur University, India, for their support in this research.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix: Uncertainty analysis

Appendix: Uncertainty analysis

Here uncertainty analysis of friction factor and Nusselt number calculation has been presented.

Friction factor

or

The uncertainty in friction factor has been calculated from the above equations.

Nusselt number

or

where \({\Delta} T_{\text{b}} = T_{\text{bo}} - T_{\text{bi}}\).

Rights and permissions

About this article

Cite this article

Bhattacharyya, S., Benim, A.C., Pathak, M. et al. Thermohydraulic characteristics of inline and staggered angular cut baffle inserts in the turbulent flow regime. J Therm Anal Calorim 140, 1519–1536 (2020). https://doi.org/10.1007/s10973-019-09094-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-019-09094-8