Abstract

Introduction

In this series of papers, we present a design of poly(methyl methacrylate) (PMMA) recycling system considering environmental impacts, chemical hazards, and resource availability. We applied life cycle assessment (LCA), environment, health, and safety (EHS) assessment as well as material flow analysis to the evaluation of the recycling system.

Purpose

Recycling systems for highly functional plastics such as PMMA have not been studied sufficiently. Along with the popularization of PMMA-containing products such as liquid crystal displays (LCDs), the use of PMMA is steadily increasing, which will result in more waste of PMMA in the next decades. In this study, pyrolysis process for recycling waste PMMA into methyl methacrylate (MMA) monomer was examined, considering not only general environmental impacts quantified by life cycle assessment but also local environment, health, and safety hazards, and raw material availability.

Methods

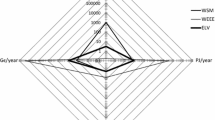

Process EHS hazards assessment was applied to quantify the local effects of the PMMA monomer recycling process. Process hazards are strongly connected with the hazardous properties of chemical substances and stream conditions within the process. Two alternative cooling methods exist, and their difference was analyzed by LCA and EHS assessment. Besides the process hazard, the availability of waste PMMA must be an important point for the feasibility of implementing the PMMA monomer recycling process. The available amount can be quantified by analyzing the material flow of PMMA-containing products. PMMA contained in LCDs as light guide panels was selected as a feasible source of waste PMMA, and the quantity of PMMA flows in the society was evaluated.

Results and discussion

In the case of PMMA, monomer recycling has less process hazard than the production of fresh MMA from crude oil. The implementation of circulated cooling water could significantly decrease the process hazard in PMMA pyrolysis attributable to chemical hazards. Material flow analysis revealed that the availability of waste PMMA shows a fluctuating trend in the next 20 years because of the sharp peak demand for LCD television sets. The fluctuation is strongly dependent on the lifetime of LCD television sets.

Conclusions

PMMA monomer recycling has a potential to reduce environmental impacts with a less process hazards than fresh MMA production from crude oil. The availability of waste PMMA has a strong relationship with the lifetime of LCD television sets. The multiple and comprehensive assessments can reveal various aspects of a process technology.

Similar content being viewed by others

References

Adu IK, Sugiyama H, Fischer U, Hungerbühler K (2008) Comparison of methods for assessing environmental, health, and safety (EHS) hazards in early phases of chemical process design. Trans IChemE: Part B Proc Saf Environ Protect 86(B2):77–93

Aktas CB, Bilec MM (2012) Service life prediction of residential interior finishes for life cycle assessment. Int J Life Cycle Assess 17:362–371

Arena U, Mastellone ML, Perugini F (2003a) The environmental performance of alternative solid waste management options: a life cycle assessment study. Chem Eng J 96:207–222

Arena U, Mastellone ML, Perugini F (2003b) Life cycle assessment of a plastic packaging recycling system. Int J Life Cycle Assess 8:92–98

Association for Electric Home Appliances, Japan (AEHA) (2010) Investigation on the elapsed years of use for four types of electric home appliances (original title in Japanese). http://www.meti.go.jp/meti_lib/report/2010fy01/E001174.pdf. Accessed 21 May 2012

Center for Chemical Process Safety (2007) Guidelines for risk based process safety. Wiley, New Jersey, USA

Centers for Disease Control and Prevention (CDC) (2012) Documentation for immediately dangerous to life or health concentrations (IDLHs), http://www.cdc.gov/niosh/idlh/intridl4.html. Accessed 21 May 2012

ChemExper Inc. (2012) ChemExper, Catalog of Chemical Suppliers, Physical Characteristics and Search Engine. URL http://www.chemexper.com/. Accessed 21 May 2012

Display Search Ltd. (2012) LCD TV Shipments to grow 7 % in 2012 to 220M units, despite zero growth in overall TV shipments. http://www.displaysearch.com/cps/rde/xchg/displaysearch/hs.xsl/120509_lcd_tv_shipments_to_grow_in_2012_to_220M_units_despite_zero_growth_in_overall_tv_shipments.asp. Accessed 21 May 2012

Environmental Protection Agency (EPA), USA (2011) Estimation Program Interface (EPI) Suite 4.10. http://www.epa.gov/oppt/exposure/pubs/episuite.htm. Accessed 21 May 2012

Fuji Chimera Research Institute, Inc (2010) Market report of plastic sheet. Fuji Chimera Research Institute, Tokyo, Japan

Hirasawa E (1999) A recycling plant for home electric appliances. Mitsubishi Electric Advance 87:7–11

Humbert S, Rossi V, Margni M, Jolliet O, Loerincik Y (2009) Life cycle assessment of two baby food packaging alternatives: glass jars vs. plastic pots, Int J Life Cycle Assess 14:95–106

International Labor Organization (ILO) (2012) The International Chemical Safety Cards (ICSC) database. http://www.ilo.org/dyn/icsc/showcard.home. Accessed 21 May 2012

Japan Electronics and Information Technology Industries Association (JEITA) (2011) Prediction of waste television sets after the sign-off of analog terrestrial broadcasting in Japan, 2011. http://home.jeita.or.jp/page_file/20110624141831_PTQuK26jpg.pdf. Accessed 21 May 2012

Japan Electronics and Information Technology Industries Association (JEITA) (2012) Statistics on domestic shipments of major consumer electronic equipment. http://www.jeita.or.jp/english/stat/index.htm. Accessed 21 May 2012

Japan Environmental Management Association for Industry (JEMAI) (2007) JEMAI-LCA Pro

Japan Petrochemical Industry Association (JPIA) (2012) Statistical data of MMA production, shipment, and stock, http://www.jpca.or.jp/4stat/00index.htm. Accessed 21 May 2012

Japan Plastics Industry Federation (JPIF) (2012) Statistical data of plastic production in 2011, http://www.jpif.gr.jp/3toukei/conts/2011/2011_genryou_c.htm. Accessed 21 May 2012

Jiménez-González C, Constable DJC (eds) (2011) Green chemistry and engineering: a practical design approach. John Wiley & Sons, New Jersey, USA

Kakudate K, Kjikawa Y, Adachi Y, Suzuki T (2002) Calculation model of CO2 emissions for Japanese cars. Int J Life Cycle Assess 7:85–93

Kaminsky W, Franck J (1991) Monomer recovery by pyrolysis of poly(methyl methacrylate) (PMMA). J Anal Appl Pyrol 19:311–318

Kikuchi Y, Hirao M (2009) Hierarchical activity model for risk-based decision making integrating life cycle and plant-specific risk assessments. J Ind Ecol 13(6):945–964

Kikuchi Y, Hirao M, Ookubo T, Sasaki A (2013) Design of recycling system for poly(methyl methacrylate) (PMMA) Part 1: recycling scenario analysis. Int J Life Cycle Assess. doi:10.1007/s11367-013-0624-y. (accepted)

Kletz TA, Amyotte P (2010) Process plants: a handbook for inherently safer design. CRC Press, Second Edition

Koller G, Fischer U, Hungerbühler K (2000) Assessing safety, health, and environmental impact during early process development. Ind Eng Chem Res 39(4):960–972

Koller G, Fischer U, Hungerbühler K (2001) Comparison of methods suitable for assessing the hazard potential of chemical processes during early design phases. Trans IChemE: Part B Proc Saf Environ Protec 79(B2):157–166

Kolluru RV, Bartell SM, Pitblado RM, Stricoff RS (1996) Risk assessment and management handbook for environmental, health, and safety professionals. McGraw-Hill, New York

Kubo Y (2011) Compression molding machine for thin-walled LCD (original title in Japanese). SangyoKikai 727:11–15

Life Cycle Assessment Society of Japan (JLCA) (2012) JLCA-LCA database 2012 1st edition http://lca-forum.org/database/. Accessed 21 May 2012

Lin CH (2008) A model using home appliance ownership data to evaluate recycling policy performance. Resour Conserv Recycl 52:1322–1328

Liu X, Tanaka M, Matsui Y (2006) Generation amount prediction and material flow analysis of electronic waste: a case study in Beijing, China. Waste Manag Res 24:434–445

Ministry of Economy, Trade, and Industry, Japan (METI) (2001), Home Appliance Recycling Act, http://www.meti.go.jp/policy/recycle/main/english/law/home.html. Accessed 21 May 2012

Ministry of Economy, Trade, and Industry, Japan (METI) (2012a) Paper, printing, plastic, rubber products statistics. http://www.meti.go.jp/statistics/tyo/seidou/result/ichiran/06_kami.html. Accessed 21 May 2012

Ministry of Economy, Trade, and Industry, Japan (METI) (2012b) Statistical survey on trends in industrial production (original title in Japanese), http://www.meti.go.jp/statistics/tyo/seidou/result/ichiran/03_kikai.html. Accessed 21 May 2012

Ministry of Internal Affairs and Communications, Japan (MIAC) (2011) Consultation center for terrestrial digital television broadcast. http://www.soumu.go.jp/main_sosiki/joho_tsusin/dtv/english/index_en.html. Accessed 21 May 2012

Nakano K, Aoki R, Yagita H, Narita N (2007) Evaluating the reduction in greenhouse gas emissions achieved by the implementation of the household appliance recycling in Japan. Int J Life Cycle Assess 12:289–298

Nakatani J, Fujii M, Moriguchi Y, Hirao M (2010) Life cycle assessment of domestic and transboundary recycling of post-consumer PET bottles. Int J Life Cycle Assess 15:590–597

National Institute for Environmental Studies, Japan (NIES) (2010) Lifespan database for Vehicles, Equipment, and Structures: LiVES. http://www.nies.go.jp/lifespan/index-e.html. Accessed 21 May 2012

National Institute of Population and Social Security Research, Japan (IPSS) (2012) Population Statistics of Japan. http://www.ipss.go.jp/syoushika/tohkei/Mainmenu.asp. Accessed 21 May 2012

PC3R Promotion Association, Japan (2004) House hold PC recycling, http://www.pc3r.jp/e/index.html. Accessed 21 May 2012

Ribeiro C, Ferreira JV, Partidário P (2006) Life cycle assessment of a multi-material car component. Int J Life Cycle Assess 12:336–345

Romero-Hernández O, Romero-Hernández S, Muñoz D, Detta-Silveira E, Palacios-Brun A, Laguna A (2009) Environmental implications and market analysis of soft drink packaging systems in Mexico. A waste management approach. Int J Life Cycle Assess 14:107–113

Scheirs J, Kaminsky W (eds) (2006) Feedstock recycling and pyrolysis of waste plastics: converting waste plastics into diesel and other fuels (Wiley Series in Polymer Science). John Wiley & Sons, Chichester

Sugiyama H (2007) Decision-making framework for chemical process design including different stages of environmental, health and safety (EHS) assessment. Dissertation ETH No. 17186, Swiss Federal Institute of Technology, Zurich

Sugiyama H, Hirao M, Fischer U, Hungerbühler K (2008a) Activity modeling for integrating environmental, health, and safety (EHS) consideration as a new element in industrial chemical process design. J Chem Eng Jpn 41(9):884–897

Sugiyama H, Fischer U, Hungerbühler K, Hirao M (2008b) Decision framework for chemical process design including different stages of environmental, health, and safety assessment. AICHE J 54(4):1037–1053

Sugiyama H, Fischer U, Antonijuana E, Hoffmann VH, Hirao M, Hungerbühler K (2009) How do different process options and evaluation settings affect economic and environmental assessments? A case study on methyl methacrylate (MMA) production processes. Process Saf Environ Prot 87:361–370

Yamasue E, Minamino R, Daigo I, Okumura H, Ishihara KN (2009) Evaluation of total materials requirement for the recycling of elements and materials (urban ore tmr) from end-of-life electric home appliances. Mater Trans 50(9):2165–2172

Yokota K, Matsuno Y, Yamashita M, Adachi Y (2003) Integration of life cycle assessment and population balance model for assessing environmental impacts of product population in a social scale. Case studies for the global warming potential of air conditioners in Japan. Int J Life Cycle Assess 8:129–136

Acknowledgments

The authors would like to thank Katsumi Fujisaki (Mitsubishi Electric Co., Ltd. and Hyper Cycle Systems Co., Ltd.) and Tsuruoka Co., Ltd. for their cooperation in the investigation of the recycling processes. The authors also thank Yuma Yuguchi for their cooperation in the simulation of process models and the collection of data for LCA. A productive discussion on MFA with Dr. Ichiro Daigo is appreciated. Part of this study was supported by a grant-in-aid for scientific research (B) (no. 23360404) and scientific research (A) (no. 24246150) from the Japan Society for the Promotion of Science. The author (Yasunori Kikuchi) was supported through the Japan Society for Promotion of Science Institutional Program for Young Researchers Overseas Visits and Young Researchers Overseas Study Program for Mechanical Systems Innovation managed by the Global COE Program, “Global Center of Excellence for Mechanical Systems Innovation,” by the Ministry of Education, Culture, Sports, Science, and Technology, Japan.

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Yasunari Matsuno

Electronic supplementary material

Below is the link to the electronic supplementary material.

ESM 1

(DOCX 361 kb)

Rights and permissions

About this article

Cite this article

Kikuchi, Y., Hirao, M., Sugiyama, H. et al. Design of recycling system for poly(methyl methacrylate) (PMMA). Part 2: process hazards and material flow analysis. Int J Life Cycle Assess 19, 307–319 (2014). https://doi.org/10.1007/s11367-013-0625-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11367-013-0625-x