Abstract

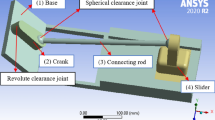

This paper deals with the static and dynamic output kinematic accuracy of a group of elastic slider-crank mechanisms with the same design parameters by taking the bar length, the joint-gaps, the mass density, and the sectional and the physical parameters as random variables. According to the principle of linear pile-up of small displacement, the static and dynamic output kinematic errors are synthesized, and the reliability model of the kinematic accuracy of the mechanism is built. Through an example, a study of the influencing factors on the reliability of the output kinematic accuracy of the mechanism is made. The results obtained reveal the following facts: with the increase of the crank’s rotating speed, the dynamic elastic deformation of the mechanism becomes the principal factor that greatly affects the reliability of the output kinematic accuracy of the mechanism.

Similar content being viewed by others

References

Bruevich N G. Mechanism Precision (in Chinese, trans. Staff Room of Theory of Machines and Part, Zhejiang University) Shanghai: Science and Technology Press, 1966

Sandler B Z. Probabilistic Approach to Mechanisms (in Chinese, trans. Ma Peisun). Beijing: Science Press, 1991

Lee S J, Gilmore B J. The determination of the probabilistic properties of velocities & accelerations in kinematics chains with uncertainty. Transactions of the ASME, 1991, 113(3): 84–90

Shi Tianlu, Feng Yuansheng. Reliability analysis of kinematic accuracy for RCCC-Spatial mechanism. Mechanical Science and Technology, 1995, 14(1): 47–51 (in Chinese)

Meng Xianju, Zhang Ce, Zhan Meijing, et al. Analytical model of accuracy probability for linkage with clearances. Journal of Machine Design, 2004, 21(9): 35–37 (in Chinese)

Chen Jianjun, Chen Yong, Cui Mintao, et al. Optimization design for flat four-bar mechanism based on reliability of kinematic accuracy. Mechanical Science and Technology, 2002, 21(6): 940–944 (in Chinese)

Feng B, Morita N, Torii T. A new optimization method for dynamic design of planar linkage with clearances at joint-optimizing the mass distribution of links to reduce the change of joint force. ASME J Mech Design, 2002, 124(1): 68–73

Li Hanyan, Zhang Xianmin, Peng Huiqing. Optimal design of compliant mechanism based on fatigue reliability. Chinese Mechanical Engineering, 2004, 15(23): 2130–2133 (in Chinese)

Zhang Ce, Huang Yongqiang, Wang Ziliang, et al. Analysis and Design of Elastic Linkage Mechanism. Mechanical Industry Press, 1989 (in Chinese)

Zhang Li, Huang Wenzhen, Zhou Zhige. Application of sensitivity analysis in dynamic response of elastic linkages. Journal of Shanghai Jiaotong University, 2000, 34(3): 378–380 (in Chinese)

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Machine Design and Research, 2006, 22(1): 26–28 [译自: 机械设计与研究]

Rights and permissions

About this article

Cite this article

Tuo, Y., Chen, J., Zhang, C. et al. Reliability analysis of kinematic accuracy for the elastic slider-crank mechanism. Front. Mech. Eng. China 2, 214–217 (2007). https://doi.org/10.1007/s11465-007-0037-3

Issue Date:

DOI: https://doi.org/10.1007/s11465-007-0037-3