Abstract

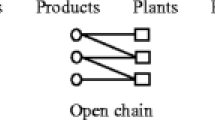

The concept of plant focus emphasizes a firm's ability to increase productivity and lower cost by limiting the number and variety of operations at its production lines. In this paper, we present a quantitative modeling framework to analyze the choice between product focus and market focus strategies. We also study the effect of flexible manufacturing technology on plant focus. Our methodology is based on a facility design model that uses continuous functions in representing the spatial distribution of demand and cost parameters. One of the advantages of this approach is its ability to generate closed-form solutions with relatively little data. Furthermore, it enables us derive several managerial insights into plant focus decisions as well as the impact of technology alternatives on these decisions. Finally, continuous approximation approach has potential to complement more detailed mixed integer models.

Similar content being viewed by others

References

Beckenbach, F.E. and R. Bellman. (1961). Inequalities. Springer-Verlag: Berlin.

Benjaafar, S. and D. Gupta. (1998). “Scope Versus Focus: Issues of Flexibility, Capacity, and the Number of Production Facilities,” IIE Transactions 30, 413–425.

Billington, A.C. and T.C. Davis. (1992). “Manufacturing Strategy Analysis: Models and Practice.” OMEGA International Journal of Management Science 20, 587–595.

Burns, D. L, R.W. Hall, D. Blumenfeld, and C.F. Daganzo. (1985). “Distribution Strategies that Minimize Transportation and Inventory Costs.” Operations Research 33, 469–490.

Buzacott, A.J. (1999). “The Structure of Manufacturing Systems: Insights on the Impact of Variability,” International Journal of Flexible Manufacturing Systems 11, 127–146.

Cohen, A.M. and S. Moon. (1991). “An Integrated Plant Loading Model with Economies of Scale and Scope.” European Journal of Operational Research 50, 266–279.

Daganzo, F. C. (1999). Logistics Systems Analysis. Springer-Verlag: Berlin Heidelberg.

Dasci, A. (2001). “Discrete and Continuous Models for Production-Distribution Systems.” PhD thesis, McGill University.

Dasci, A. and V. Verter. (2001a). “A Continuous Model for Production-Distribution System Design Problem.” European Journal of Operational Research 129, 287–298.

Dasci, A. and V. Verter. (2001b). “The Plant Location and Technology Acquisition Problem.” IIE Transactions 33, 963–973.

Erlebacher, J.S. and R.D. Meller. (2000). “The Interaction of Location and Inventory in Designing Distribution Systems.” IIE Transactions 32, 155–166.

Erlenkotter, D. (1989). “The General Market Area Model.” Annals of Operations Research 18, 45–70.

Fine, H.C. and R.M. Freund. (1990). “Optimal Investment in Product-Flexible Manufacturing Capacity.” Management Science 36, 449–466.

Geoffrion, M.A. (1979). “Making Better use of Optimization Capability in Distribution System Planning.” AIIE Transactions 11, 96–108.

Hall, W.R. (1993). “Design for Local Area Freight Networks.” Transportation Research B 27B, 79–95.

Hayes, H.R. and S.C. Wheelwright. (1984). Restoring Our Competitive Edge. New York: John Wiley.

Klincewicz, G.J. and H. Luss. (1987). “A Dual Based Algorithm for Multiproduct Uncapacitated Facility Location.” Transportation Science 21, 198–206.

Langevin, A., P. Mbaraga, and J.F. Campbell. (1996). “Continuous Approximation Models in Freight Distribution: An Overview. Transportation Research B 30, 163–188.

Li, S. and D. Tirupati. (1994). “Dynamic Capacity Expansion Problem with Multiple Products: Technology Selection and Timing of Capacity Additions.” Operations Research 42, 958–976.

Miller, G.J. and A.V. Roth. (1994). “A Taxonomy of Manufacturing Strategies.” Management Science 40, 285–304.

Newell. F.G. (1973). “Scheduling, Location, Transportation, and Continuum Mechanics; some Simple Approximations to Optimization Problems.” SIAM Journal of Applied Mathematics 25, 346–360.

Rosenfield, B. D., I. Engelstein, and D. Feigenbaum. (1992). “An Application of Sizing Service Territories.” European Journal of Operational Research 63, 164–172.

Schmenner, W.R. (1982). Making Business Location Decisions. Englewood Cliffs, NJ: Prentice Hall.

Skinner, W. (1974). “The Focused Factory.” Harvard Business Review May-June, 113–121.

Suzuki, T., Y. Asami, and A. Okabe. (1991). “Sequential Location-Allocation of Public Facilities in One- and Two-Dimensional Space: Comparison of Several Policies.” Mathematical Programming 52, 125–146.

van Mieghem, A.J. (1998). “Investment Strategies for Flexible Resources.” Management Science 44, 1071–1078.

Verter, V. and A. Dasci. (2002). “The Plant Location and Flexible Technology Acquisition Problem.” European Journal of Operational Research 136, 366–382.

Warszawski, A. (1973). “Multi-Dimensional Location Problems.” Operational Research Quarterly 24, 165–179.

Scott W. and A. Gupta. (1995). “The General Optimal Market Area Model with Uncertain and Nonstationary Demand.” Location Science 3, 25–38.

Author information

Authors and Affiliations

Corresponding author

Additional information

This research was partially funded by the Natural Sciences and Engineering Council of Canada (OGP 183631) and the Canada Research Chair in Distribution Management at HEC Montreal. Both authors are affiliated with the Center for Research on Transportation, which provided an excellent environment for collaboration. Three anynomuous referees and Gilbert Laporte, the guest co-editor, provided very helpful comments on an earlier draft of the paper.

Rights and permissions

About this article

Cite this article

Dasci, A., Verter, V. Evaluation of Plant Focus Strategies: A Continuous Approximation Framework. Ann Oper Res 136, 303–327 (2005). https://doi.org/10.1007/s10479-005-2061-1

Issue Date:

DOI: https://doi.org/10.1007/s10479-005-2061-1